- No. 268 Xianghe Street, Economic Development Zone of Xingtai city, Hebei 054001 China

- Byron@hbhongri.cn

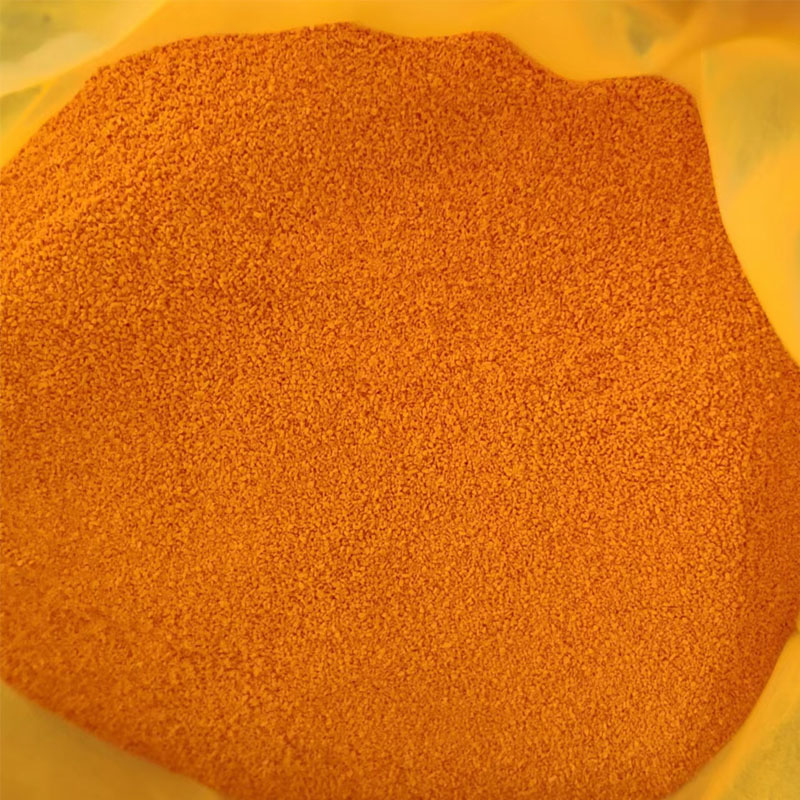

High-Quality Red Pepper Powder Production Facility for Premium Culinary Spice Manufacturing

Exploring the World of Fine Red Pepper Powder A Glimpse into the Factory Process

In the bustling world of spice production, few ingredients command as much attention and appreciation as fine red pepper powder. Known for its vibrant color and distinct flavor, this spice has a rich history and a significant role in cuisines around the globe. Behind this culinary staple lies a complex and meticulous production process that takes place in specialized factories dedicated to transforming fresh peppers into fine red pepper powder.

The journey of fine red pepper powder begins in the fields, where various types of peppers, such as cayenne, paprika, and chili, are cultivated. These peppers are selected for their quality, flavor, and heat level, making them suitable for various culinary applications. Once harvested, the peppers undergo a thorough quality check to ensure that only the best specimens make it to the processing stage.

Exploring the World of Fine Red Pepper Powder A Glimpse into the Factory Process

Once dried, the peppers are cleaned to remove any impurities such as dirt, stems, and seeds. This is often achieved through a combination of manual and mechanical processes, ensuring that the final powder is pure and free from contaminants. Cleaned and dried, the peppers are now ready for grinding.

fine red pepper powder factory

The grinding process is where the magic happens. Depending on the desired fineness of the powder, the peppers are ground using specialized machinery. Factories often employ hammer mills or spice grinders, which can produce various textures from coarse flakes to ultra-fine powders. Achieving the right granularity is essential, as it affects how well the spice integrates into dishes and its flavor release during cooking.

Quality control is a paramount aspect of the production process. Throughout the grinding stage, samples are taken to ensure consistency in color, flavor, and heat. Many factories employ stringent testing methods to analyze the spice's chemical composition, ensuring that it meets health and safety standards. This includes checking for aflatoxins, microbial content, and allergens, which are crucial for consumer safety.

Once the grinding and quality checks are complete, the fine red pepper powder is packaged. Packaging plays a significant role in preserving the quality of spices. Factories use airtight containers that are often UV-protected to prevent light from degrading the color and flavor of the powder. Proper labeling is also essential, providing consumers with information about the product, including its origin, heat level, and best-by date.

In recent years, there has been a growing emphasis on sustainability in spice production. Many factories are now seeking ways to minimize waste, use eco-friendly packaging, and source peppers from local farmers who employ sustainable farming practices. This commitment to sustainability not only benefits the environment but also supports local economies and promotes ethical consumption.

In conclusion, the production of fine red pepper powder in factories is a fascinating blend of agriculture, technology, and culinary tradition. From the careful selection of peppers to the precise grinding and stringent quality control, each step is crucial in delivering a product that enhances flavors in kitchens around the world. As consumers become more aware of the origins and quality of their ingredients, the importance of these factories and their processes will only continue to grow, ensuring that fine red pepper powder remains a beloved staple in global cuisine.

-

Turmeric Rhizome Powder: A Golden Treasure from Roots to TableNewsJul.28,2025

-

The Versatile Application Of Crushed Red Hot Peppers: Lighting Up The Red Flames On The Dining TableNewsJul.28,2025

-

The Paprika: A Touch Of Vibrant Red In Color, Flavor, And CultureNewsJul.28,2025

-

Ground Turmeric: A Modern Examination of an Ancient SpiceNewsJul.28,2025

-

Capsicum Liquid Extract: Features, Applications, and ChallengesNewsJul.28,2025

-

Application of Capsicum Liquid Extract in FoodNewsJul.28,2025